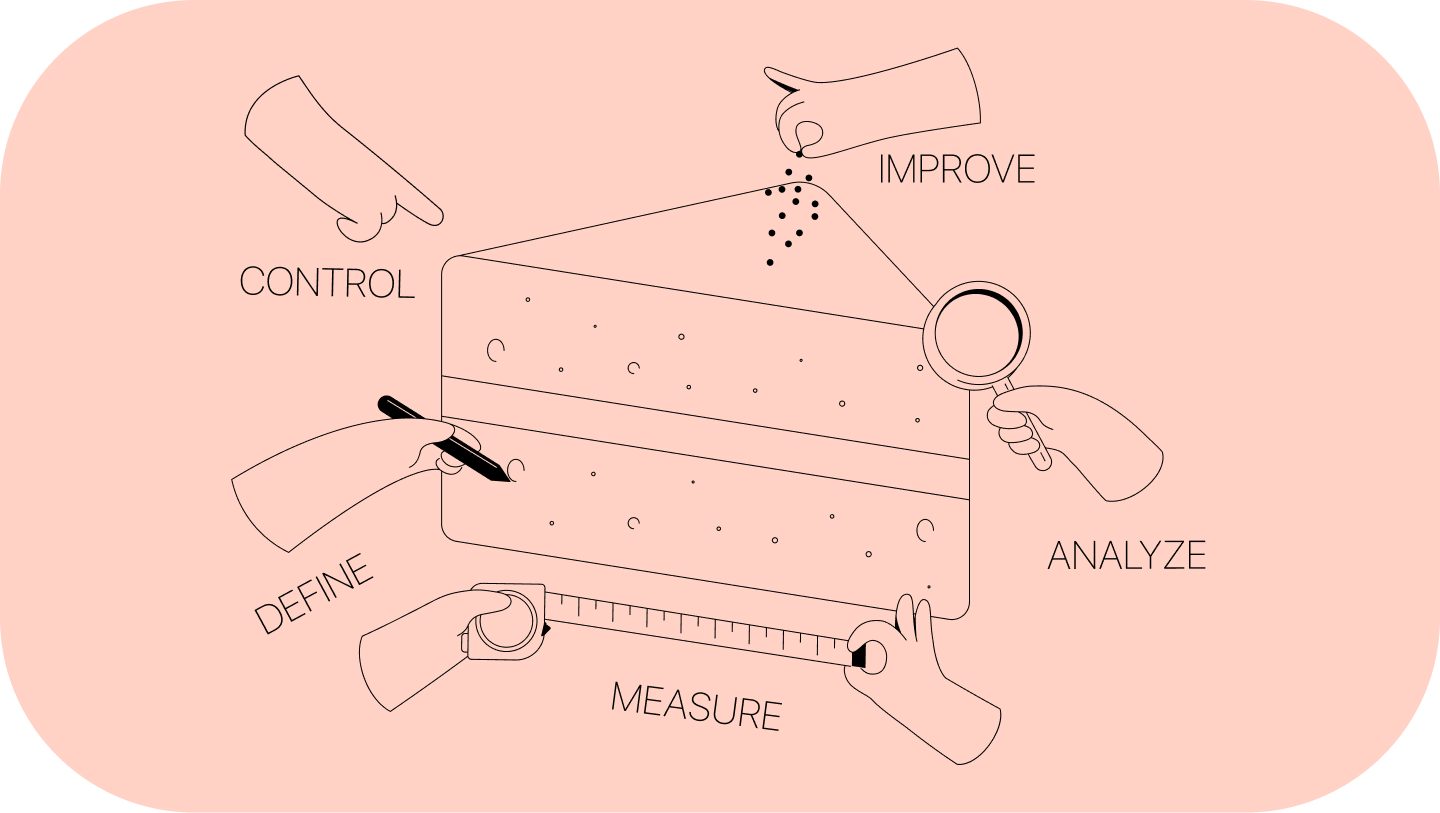

Engineers at Motorola developed a scale that should evaluate the quality of processes based on their defects. Six Sigma is at the top of the scale, which is 99.9997% defect-free. In other words, if you make a million car cylinders, there will only be 3.4 defects. This means that if your processes run at Six Sigma, they almost have no defects.

The Six Sigma scale shows how well an important feature performs compared to its requirements. The lower the sigma level, the bigger the number of defects. Naturally, most businesses operate at 4 or 5 Sigma, which means that the losses that result from poor quality cost them 10-15% of their revenue.