Agile

- Agile is a philosophy

- Depends on storyboards

- Iterative development is allowed

- Breaks the entire project into smaller pieces

This method is based on the philosophy that you should gradually improve whatever you’re working on, and progress is expected over time. If you’re a visual thinker, you’ll love Kanban! It helps teams in their planning practices by visualizing and prioritizing elements on boards.

Kanban is a methodology that nests under the umbrella of the Agile philosophy. While they are based on the same principles, Kanban is one of the practical ways to implement Agile.

Kanban project management is a philosophy that suggests that you can gradually improve whatever you are working on and implement continuous, incremental, and evolutionary changes. To achieve this goal, you need to follow the four basic principles that underlie this revolutionary method:

The good thing about Kanban is that you don’t need to make big changes before implementing this methodology. You can simply overlay Kanban properties on your existing workflow, address issues, and make some important changes over time.

Encourage small but evolutionary process changes and project management that will meet minimal resistance.

While you may be satisfied with how certain elements and processes are working, you also need to seek out a way to drive out fear to be able to make necessary future changes. By agreeing to respect the current roles, responsibilities, and process, you will gain broader support for the Kanban initiative. This will help you implement the Kanban method more easily.

You don’t need to be a team leader or an executive to encourage continual improvement and reach optimal results. With Kanban, some of the best leadership comes from everyday acts by common people who are a part of a team.

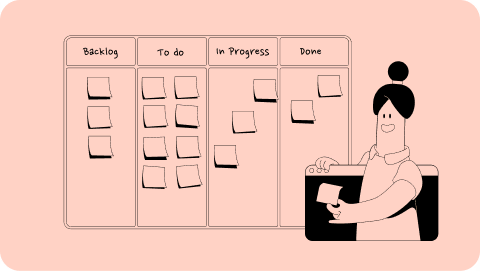

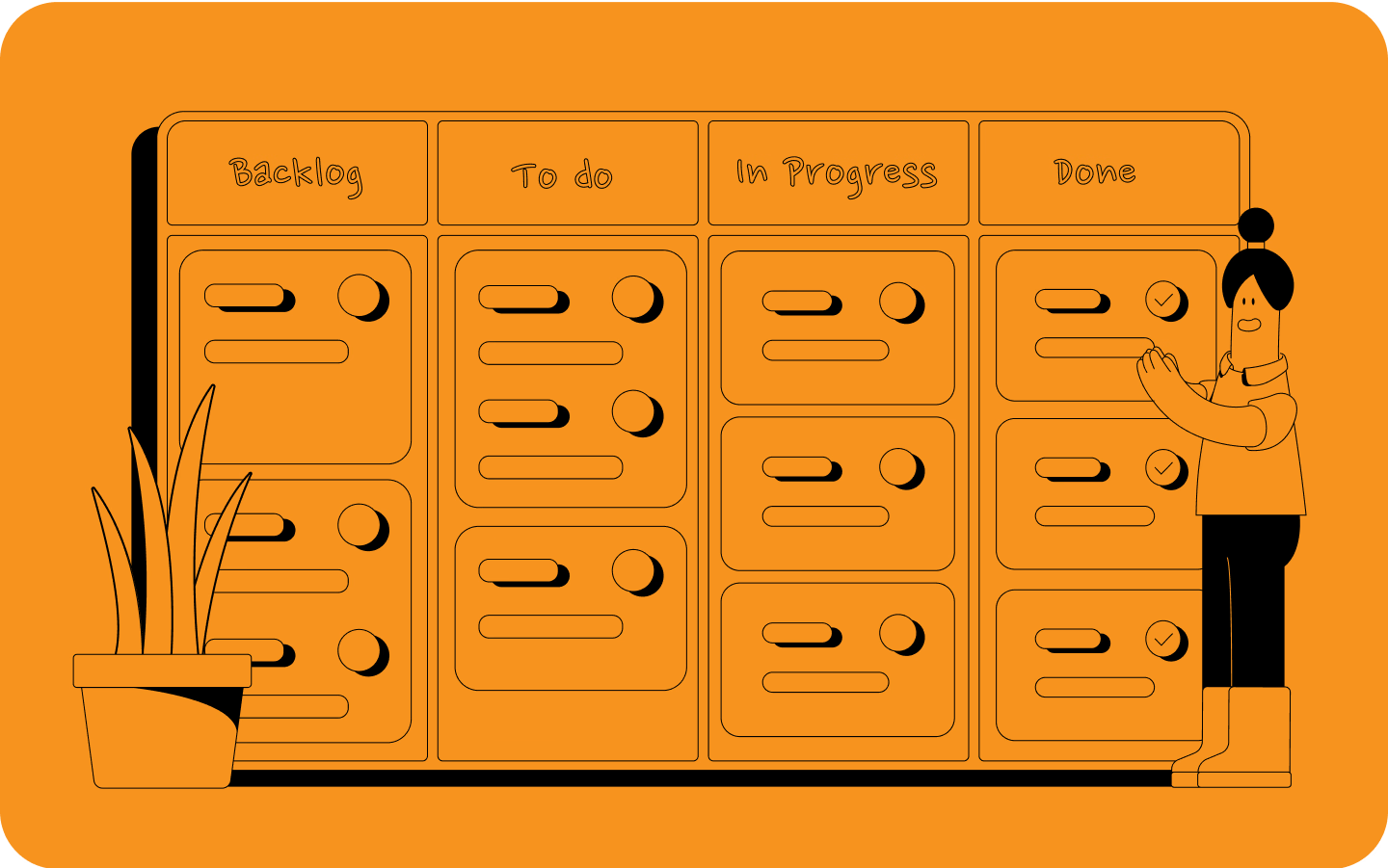

The integral part of the Kanban board is Kanban cards. Each card represents an individual work item or a task, and each consists of important data for that specific task. Cards are visually placed on the board to show the current stage of the task, and they are usually color-coded to show what type of task they are.

The Kanban board consists of three sections:

• Waiting

• Work in progress

• Completed work

After the tasks have been delegated, the team will take the cards and move them across the sections as they complete their tasks.

A Kanban board is a field on which Kanban Cards represent the individual tasks in progress, which are categorized according to priority and delivery. Simply put, Kanban is an excellent way to keep track of your team’s workflow. Today, Kanban boards are mostly used in Agile or Lean software development teams as online collaboration tools to boost team productivity and stimulate inspiring ideas.

Remember that a Kanban board can be used in many forms and that today, teams use it in different ways to share ideas and manage their workflow. The most straightforward way is the old concept of putting sticky notes on a whiteboard to show the stages of the project development and its progress.

Kanban is based on the pull system. Whether you’re a project manager in a small business or anywhere else on the value chain, pull systems will help you minimize inventories and change what's necessary for the production system as the demand arises. They provide you only with what you need, reducing costs and waste.

Read more on Scrum and Agile

Learn more about project management

As mentioned before, Kanban is an approach that will help you make changes to the management designed to meet minimal resistance. Therefore, if some processes are working well, Kanban will help you improve over time without massive and radical change.

Kanban is a great solution for projects of different sizes, complexities, and urgencies. Although Kanban works well in most industries, the practice has proven that it works best in the product development environment.

Finally, If you want to build trust within your organization and take productivity to a new level, opt for Kanban and see how it works for your business.

Here’s how to implement Kanban in five steps:

Visualize workflow— Get a board, divide it into columns, and stick your team’s tasks on it. It can be a physical whiteboard on a wall or a digital one. It doesn’t matter as long as it’s accessible to everyone.

Limit WIP (Work-In-Progress)— Focusing on one activity at a time is important. This part is often overlooked, even though it ensures the efficiency and productivity Kanban stands for. Limit the number of ongoing activities, and be sure to follow through.

Make policies explicit— Once rules and procedures are set, teams can be sure they're operating consistently at the desired level of quality.

Managing and measuring workflow— Tracking and reviewing Kanban data such as lead time, cycle time, and throughput is essential, so the team can monitor their processes.

Optimize scientifically— When you want to make a change, set up a hypothesis, jot down the current results, make the change, and then measure the difference it made. If the results are not satisfactory, switch back.

Continue reading

Project Management Methodologies Introduction

Get familiar with the most popular methodologies modern project managers use! Learn the basics and choose the best method to manage your teams and projects.